How To Change A Lock To Zero Bit

How to Reinforce Doors: Entry Door and Lock Reinforcements

Iii elementary upgrades to improve door security

Prevent suspension-ins by upgrading and strengthening your deadbolt and lockset. Larn how to install a Course one deadbolt, how to install a 4-screw strike plate box, and how to beef upwardly the lockset strike plate to protect your domicile.

Y'all might likewise like: TBD

- Fourth dimension

- Complication

- Cost

- A full day

- Beginner

- $101–250

Stride 1: Overview of door security locks

I never realized how easy it is to boot in a solid door that has old hardware until I tried it on our sit-in door. With two kicks in only five seconds, I destroyed the doorjamb and was in the house.

Y'all need to upgrade the deadbolt and lockset plates of your exterior doors if you oasis't already washed so. FBI break-in statistics testify that 65 percent of abode interruption-ins occur by forcing in the front, back or garage service door (not to mention the 12 percentage of entries where burglars find your "hidden" primal or simply walk in through an unlocked door).

In this story, we'll show you how to strengthen your exterior secure doors in 3 ways. Nosotros'll supercede an erstwhile deadbolt with a quality Grade one deadbolt. Then, nosotros'll replace the deadbolt door strike plate with a iv-screw strike box and faceplate—attached with 3-in. wood screws that accomplish the wall frame. Finally, nosotros'll replace the lip door strike plate and its wimpy 3/four-in. screws with 3-in. wood screws. We'll also bear witness you lot a handy method to turn a pocket-sized deadbolt hole into a larger hole.

The techniques nosotros prove in this article will work on any type of exterior door. But go on in mind that these techniques may not be as effective if you have glass sidelight windows or large glass panels in your doors.

For this project, you need only basic carpentry tools, as well as a 2-i/8 in. hole saw bit and a one-in. spade bit (check the deadbolt packaging for the exact flake size required). Habitation centers ordinarily carry deadbolt installation kits with the right size $.25.

Step 2: Check all exterior doors

A secure entry starts with a solid door and a Grade ane or Grade ii deadbolt with a solid ane-in. long throw commodities (run across "Buying a Deadbolt"). Any outside door that but has a lock in the doorknob isn't secure. A sturdy screwdriver or pocket-size pry bar tin speedily bow the doorjamb enough to release the latch.

Check your existing deadbolt. First, make certain the screws are tight. Open the door and extend the throw commodities. If it extends less than ane in., or if it's wobbly, a new deadbolt volition be more secure.

Next, bank check the doorjamb and both strike plates. Remove the screws from the deadbolt and lockset strike plates on the door frame. If the screws aren't three in. long, replace them, and as well upgrade both plates. (Note: Use shorter screws if sidelight windows are less than iii in. from the doorjamb.) These longer screws volition reinforce the doorjamb, which is a vulnerable spot.

Footstep 3: Replace the deadbolt

How to Replace a Deadbolt

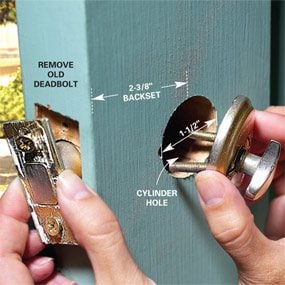

Brainstorm by removing the old deadbolt. Almost all types are held by ii screws on the interior side of the door and two screws on the faceplate (Photo one). Mensurate the cylinder hole size and the "backset" distance, that is, the distance from the center of the hole to the door edge (Photo ane). You'll demand these dimensions when you buy a new deadbolt.

Photo 2 shows how to overstate a deadbolt hole using scrap lumber, a task that is only necessary if your new deadbolt is too big to fit the existing hole (the normal size for a cylinder hole is 2-1/8 in.). The flake lath engages the center guide bit of the hole saw and keeps the new hole centered. Otherwise, you lot can't go a make clean and authentic cut.

To find the starting indicate for the hole saw bit, clamp the scrap board to the door and mark both the vertical and the horizontal heart of the new cylinder hole. Make sure to concord the drill level and straight so the hole saw bit doesn't bind and wiggle your wrist and arm. If y'all don't have a full-depth pigsty saw bit, flake the wood away from a partially drilled hole, then continue drilling. Get ho-hum so you don't splinter the reverse side when the bit goes through the door.

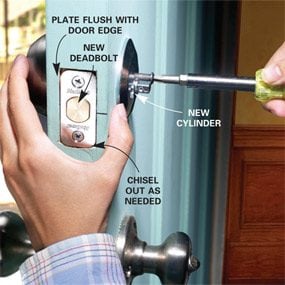

Now clean up the hole and test-fit the deadbolt. If the throw-bolt pigsty (which runs from the cylinder hole to the door edge) is too pocket-sized, make clean information technology out with a file. Make sure the fastened throw-commodities door strike plate fits flush (Photo 3), then adhere the bolt followed by the deadbolt cylinder. Paw-bulldoze the screws; a power drill may strip the threads.

Odds of Home Burglary*

Your business firm is at greater risk of burglary if:

- It sits on a corner lot (more visible to a browsing burglar and a natural place to stop and ask for directions)

- It is located close to a major highway go out (less than ane mile)

- It is located on a through street, which gives a burglar a quicker escape (dead-end streets and cul-de-sacs are safer)

- It borders a wooded area or playground (provides concealed access for burglars)

- Information technology is in a wealthier neighborhood

- It features no signs of immature children living there (burglars avoid as someone may be home)

- It was recently purchased (burglars know you haven't still developed shut familiarity with neighbors).

Effective burglary deterrents:*

- Infiltrator alarm installed

- Deadbolt locks on all secure doors

- Firm is occupied

- Newspaper and mail picked upwards

- Lights and noise (TV, radio) within house (attack timer when gone)

- Car in the driveway

- Motion-activated exterior lights

- Dog in the firm.

(*Taken from a research study, "Knowing Your Odds: Home Burglary and the Odds Ratio," by South. Hakim, One thousand. Renger and Y. Shachamurove, City College of New York and University of Pennsylvania, Sept. 2000)

Step 4: Replace the lockset door strike plate

To further reinforce the doorjamb, install a new strike plate in place of the old lip door strike plate that serves the doorknob lockset. Attach information technology with iii-in. screws. Make sure the screwheads seat flush with the confront of the strike plate. We used No. 8 x 3-in. screws. No. 10 x 3-in. screws (used for the deadbolt plate) were too big. Remember to bending the screws back slightly to be sure to catch the framing (Figure A). Again, you may take to chisel a slightly larger mortise and predrill to drive the screws.

Buying a Deadbolt

Almost people choose a deadbolt for its colour or finish, simply when entry door security locks are paramount, the critical deadbolt feature is its grade. The American National Standards Establish (ANSI) subjects all locks and components to attacks by hammers, saws, wrenches and other tools. And then information technology grades the lock: Grade 1 (all-time and toughest), Grade 2 or Grade 3.

Nearly locks you lot find in habitation centers and hardware stores are Class ii or iii. Some Grade ii locks may list Grade ane components on the package, just that doesn't requite the lock a Form one rating. However, Grade two is nonetheless a skillful-quality lock for residential employ. We only found 1 fully compliant Grade 1 deadbolt in local home centers and hardware stores. Professional locksmiths also are a good resources to find Grade 1 deadbolts.

Before you shop for a deadbolt, measure the hole size where the current cylinder fits, likewise equally the "backset" altitude from the middle of the cylinder hole to the edge of the door (Photograph 1, Step three). Nigh new deadbolts crave a ii-ane/viii in. cylinder hole, but some of them have inserts to fit the smaller 1-1/ii in. hole, so you don't have to drill to enlarge the pigsty (Photo 2, Step 3).

The backset distance is ordinarily either ii-3/eight or two-3/4 in., so make sure the new deadbolt has the identical backset. Most new locks are adjustable to fit either backset dimension. Just read the box carefully (yous may have to open up information technology and read the directions to find the information).

Likewise decide whether to buy a single cylinder (keyed on exterior side of lock just) or a double cylinder deadbolt (keyed on both sides). Cheque local building codes too, as they may prohibit double cylinder locks for burn down safety reasons (it's more difficult to escape because you must have the fundamental).

Step 5: Supervene upon the deadbolt strike plate

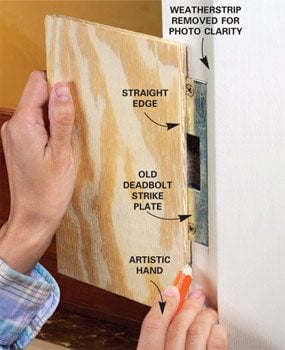

Install a heavy-duty door strike plate lock to strengthen the doorjamb. We didn't use the strike plate lock that came with the deadbolt. We opted for a more secure strike box plate that features four screws instead of ii. (2 screws are installed inside the strike box to add strength; see Photograph six.) Marker the center of the old deadbolt strike plate (Photo 1), and so temporarily install the new faceplate and deeply score around it to marking its position (Photograph 2).

Next, remove the plate, then chisel and drill out space for both the new plate and the strike box. If the strike box is larger than the existing pigsty, utilise a 1-in. spade bit to bore two holes, spaced apart the width and the depth of the box (Photo 3).

Now, remove the wood with a wood chisel to fit both the strike box plate and the faceplate (Photograph 4). Be certain to use the wood chisel with the bevel side against the wood to keep from gouging as well deep.

Finally, mount the plate and box and attach them with four 3-in. screws (Photo 5). Predrill pilot holes into the wall studs to brand the screws easier to bulldoze. Gear up the screws snug to the plate; overdriving might bow the jamb.

At present, kick back and rest a little easier, knowing yous've fabricated your home more secure.

Figure A: Doorjamb Cutaway

3-inch screws will become through the frame and penetrate the wall studs 1-1/2 to 2 in. Bending the screws back slightly into the wall to make certain they hit the studs. The studs become the primary door reinforcement, not the jamb.

Required Tools for this door reinforcement Projection

Accept the necessary tools for this DIY projection lined up before you lot first—you'll save time and frustration.

Y'all'll need this specific bits for your drill:

2 1/8 in. hole saw,

1 In. spade bit

Required Materials for this door reinforcement Project

Avoid last-minute shopping trips past having all your materials fix ahead of time. Hither'southward a list.

Source: https://www.familyhandyman.com/project/how-to-reinforce-doors-entry-door-and-lock-reinforcements/

Posted by: wilsongrem1973.blogspot.com

0 Response to "How To Change A Lock To Zero Bit"

Post a Comment